Early Porsche 911 Bosch Distributors

Bosch distributors for use in early Porsche 911s, including cast iron and aluminum type. Rebuilding includes new hardware, shims, thrust washers, insulators, sliding plates, springs, and other components as needed. Each is adjusted and tested on a Sun 404 distributor testing machine. All distributors come with cap, rotor, points, and condenser. Rev limiting rotors are an extra cost. Bosch distributor models for early 911s are pictured and listed below.

Bosch distributors for early Porsche 911s were originally the cast iron type until about 1968 when aluminum bodied units were introduced. The advance curves for 911 distributors are often two stages, created my a unequal weighting and configuration of the casting arms. This can be seen in several of the advance curves below, shown together with pictures of the advance assemblies. Distributors like the 0 231 121 006 reaches a maximum advance near 30° at high revs, needing less static advance than distributors like the 0 231 159 002. Porsche matched distributors to engine and model type as shown in the table below. Some degree of crossover is possible, as is some 'tuning' of the advance curve. But hard limits and transitions are determined by the design of the advance mechanism and are difficult to modify. In most cases, the distributor designed for a particular Porsche model is the best choice.

______________________________________________

Early 911 Distributor Types

Distributor Model Application

| 0 231 121 006 | 1965-67 911 2.0L |

| 0 231 159 001 | 1967 911T/911L 2.0L |

| 0 231 159 002 | 1967 911S 2.0L |

| 0 231 159 006 | 1969-71 911E 2.0/2.2L |

| 0 231 159 007 | 1969-71 911S 2.0/2.2L |

| 0 231 159 008 | 1970-71 911T 2.2L |

| 0 231 169 001 | 1968 2.0L |

| 0 231 169 003 | 1972-73 911T 2.4L |

| 0 231 169 004 | 1972 911E 2.4L |

| 0 231 169 005 | 1972 911S 2.4L |

| 0 231 169 008 | 1973 911T 2.4L |

| 0 231 169 009 | 1973 911E 2.4L |

| 0 231 169 010 | 1973 911S 2.4L |

| 0 231 184 001 | 1974-77 911/911S 2.7L |

| 0 231 184 007 | 1974-77 911/911S 2.7L |

______________________________________________

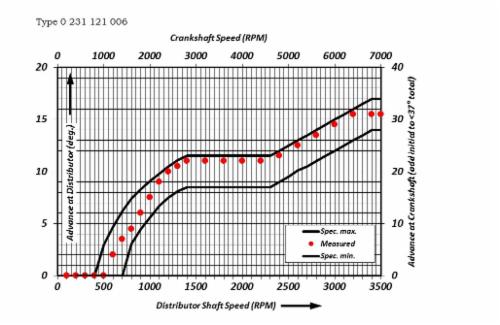

Bosch 121 006 Distributor (1965-67 911 2.0L)

Advance for the 121 006 distributor starts at about 500RPM at the distributor (1000 RPM at the crank) and advances toward about 10° at about 1200RPM. The dual advance mechanism is achieved through the use of two separately weighted arms of different length. Advance remains steady until about 2300RPM, where it increases again toward 15° at the distributor (30° at the crank) and leveling off at about 3400RPM (6800RPM at the crank). An initial static advance of 5-7°should be added to keep total advance below 37°.

121 006 Example Advance Curve

121 006 Advance Arms and Mechanism

______________________________________________

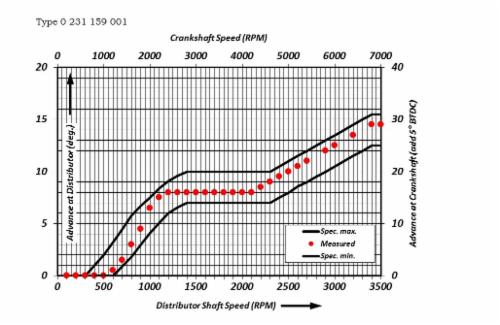

Bosch 159 001 Distributor (1966-67 911T and 911L 2.0 L)

Advance for the 159 001 distributor starts at about 500RPM at the distributor (1000 RPM at the crank) and advances toward about 8.5° at about 1200RPM. The dual advance mechanism is achieved through the use of two separately weighted arms of different length. Advance remains steady until about 2100RPM, where it increases again toward 14° at the distributor (28° at the crank) and leveling off at about 3400RPM (6800RPM at the crank). An initial static advance should be added to keep total advance below 37°.

159 001 Example Advance Curve

____________________________________________

____________________________________________

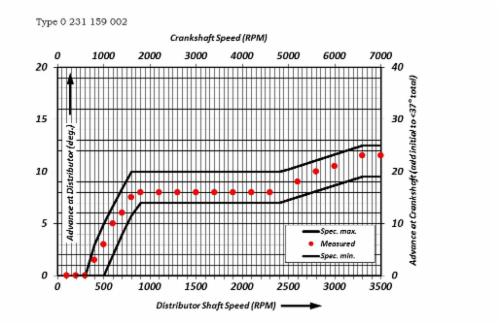

Bosch 159 002 Distributor (1967 911S 2.0 L)

Advance for the 159 002 distributor starts at about 500RPM at the distributor (1000 RPM at the crank) and advances toward about 8.5° at about 900RPM. The dual advance mechanism is achieved through the use of two separately weighted arms of different length. Advance remains steady until about 2400RPM, where it increases again toward 11.5° at the distributor (23° at the crank) and leveling off at about 3400RPM (6800RPM at the crank). An initial static advance should be added to keep total advance below 37°.

159 002 Example Advance Curve

159 002 Advance Arms and Mechanism

______________________________________________

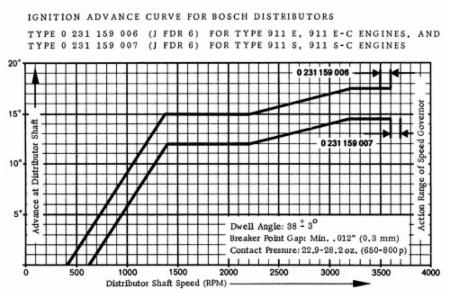

Bosch 159 006(E)/007(S) Distributors (1969-71 2-2.2L)

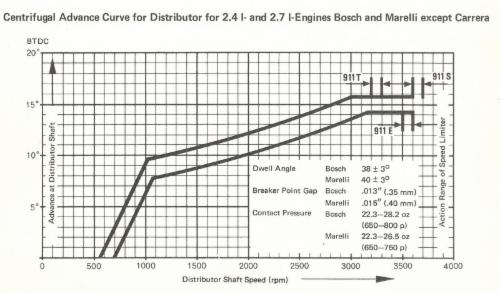

Bosch Advance Curve

Advance at distributor should fall between limits on the plot. The difference between the 006 and the 007 is the advance limiting rotor used for each 911 type (7300RPM for the 911S and 7100 for the 911E).

______________________________________________

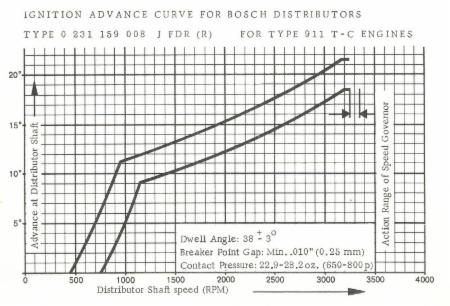

Bosch 159 008 Distributor (1970-71 911T 2.2L)

Bosch Advance Curve

Advance at distributor should fall between limits on the plot. The maximum advance (set by the rev limiting rotor) is 6500RPM)

______________________________________________

Bosch 169 008(T)/009(E)/010(S) Distributors (2.4L)

Bosch Advance Curve

Advance at distributor should fall between limits on the plot. The difference between the 008, 009, and the 010 is the advance limiting rotor used for each 911 type (7300RPM for the 911S, 7100 for the 911E, and 6500 for the 911T).

______________________________________________

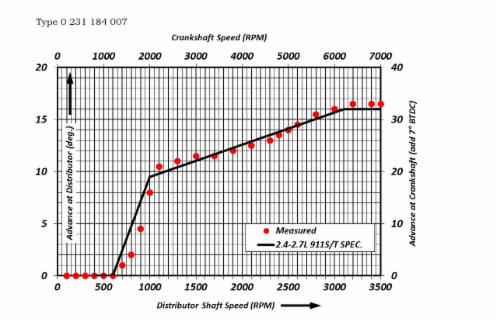

Bosch 184 007 Distributor (1974-77 911/911S 2.7L)

184 007 Example Advance Curve

Advance for the 84 007 distributor starts at about 600RPM at the distributor (1200 RPM at the crank) and advances toward about 10° at about 1000RPM. The dual advance mechanism is achieved through the use of two separately weighted arms of different length. Advance continues until about 3000RPM (6000RPM at the crank), leveling off at about 16° (32° at the crank). An initial static advance of 5°should be added to keep total advance below about 37°.

_____________________________________________

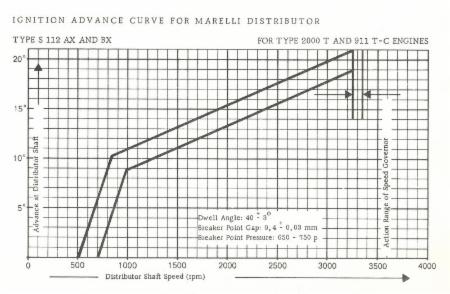

Marelli 112 AX and BX Distributors (1970-71 911T)

Marelli Advance Curve

Advance at distributor should fall between limits on the plot. The maximum advance (set by the rev limiting rotor) is 6500RPM.

_____________________________________________

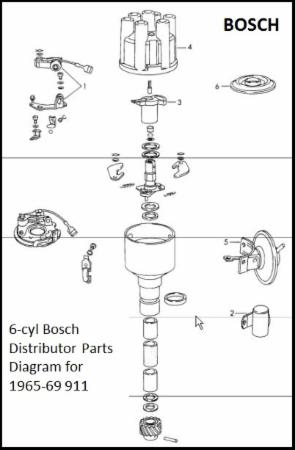

Rebuild Parts for Bosch Distributors

CFI rebuilds Bosch distributor parts using OEM or original spec. replacement parts to achieve like-new appearance and function. Standard Bosch replacement parts include those below, which are common across most Bosch distributors.

Bosch Part # Description

| 1 237 010 007 | Shims, spacers, clips, felt plugs, and o-ring kit |

| 1 237 011 500 | Terminal and insulator kit |

BOSCH Distributor Parts Diagram

The Rebuild Process

All hardware is cleaned and plated or replaced as needed. Cast iron bodies are cleaned, acid-etch primed, and painted to match factory finish. The ID tag is replaced if needed and available. Internal fiber thrust washers are replaced with OEM or Delrin washers to spec. Slider plates are replaced with new to spec. Friction and contact areas are inspected and polished. Bushings and springs are inspected and replaced if needed. All moving parts are confirmed to operate as new. Breaker plates are cleaned and nickel plated as needed. Functional tests include electrical resistance, breaker point tension, cam lobe accuracy, breaker alignment, point dwell and variation, centrifugal advance calibration, and vacuum breaker and advance (when applicable). Condenser is tested and rewired or replaced. Condenser bracket is replated or replaced. Shaft play is tested and end play is adjusted to <0.1mm as per spec. Points, rotor, and cap are replaced.